A project manager once told me that a single wrong material choice delayed his entire site by ten days. He chose the wrong pipe grade. His team paid the price. Many contractors face the same challenge today.

This guide helps B2B buyers make the right call.

1. Overview of Industrial Pipe Types

Across construction and industrial work, three materials dominate. The GI is used for water supply and structural support. The MS pipe is used for fabrication, frames, and general engineering. The SS is used for chemical plants, food units, and hygiene-sensitive systems.

According to BIS manufacturing data, India’s steel market grows at 6.5% annually (Source: BIS Annual Steel Report). Demand for galvanized and stainless variants increases each year due to infrastructure expansion (Source: Indian Steel Association).

Your choice impacts lifespan, compliance, budgets, and maintenance cycles.

2. Application Comparison

2.1 Construction and Infrastructure

A GI works well in outdoor water lines and light structures.

An MS fits heavy structures and fabrication frames.

An SS is preferred where corrosion risks are critical.

2.2 Industrial Fabrication

Fabricators choose an MS for bending, welding, and machining.

Food and chemical units mostly select an SS for hygiene and acid resistance.

2.3 Plumbing and Water Systems

A GI performs reliably in pressurized water lines.

An SS delivers long life in premium plumbing systems.

2.4 Hardware & Trading Markets

Dealers report rising demand for GI and MS pipe in tier-2 industrial zones (Source: FIEO 2024 Domestic Metals Report).

3. Price Comparison and Market Trend

Indian steel pricing fluctuates 3–7% monthly due to raw material shifts (Source: JPC Market Report).

Cost depends on coating, grade, wall thickness, finishing, and transport conditions.

Below is a simple comparison snapshot:

Pipe Cost Table (Approx. Market Trend)

| Pipe Type | Avg Price Range (per kg) | Typical Use |

|---|---|---|

| GI Pipe | ₹70–₹95 | Water lines, structures |

| MS Pipe | ₹55–₹70 | Fabrication, frames |

| SS Pipe | ₹180–₹350 | Chemical, food, premium plumbing |

Prices vary by size, brand, and coating thickness.

4. Key Factors Affecting Prices

4.1 Raw Material Costs

Iron ore and nickel fluctuations influence MS and SS pipe prices.

4.2 Coating and Grade

Zinc coating thickness increases the cost of a GI pipe.

Higher chromium and nickel levels make an SS pipe more expensive.

4.3 Fabrication Requirements

Custom cutting, threading, and bending add cost to any variant.

4.4 Size and Standard

Larger diameters and heavier schedules raise the cost of a GI, MS,or SS pipe.

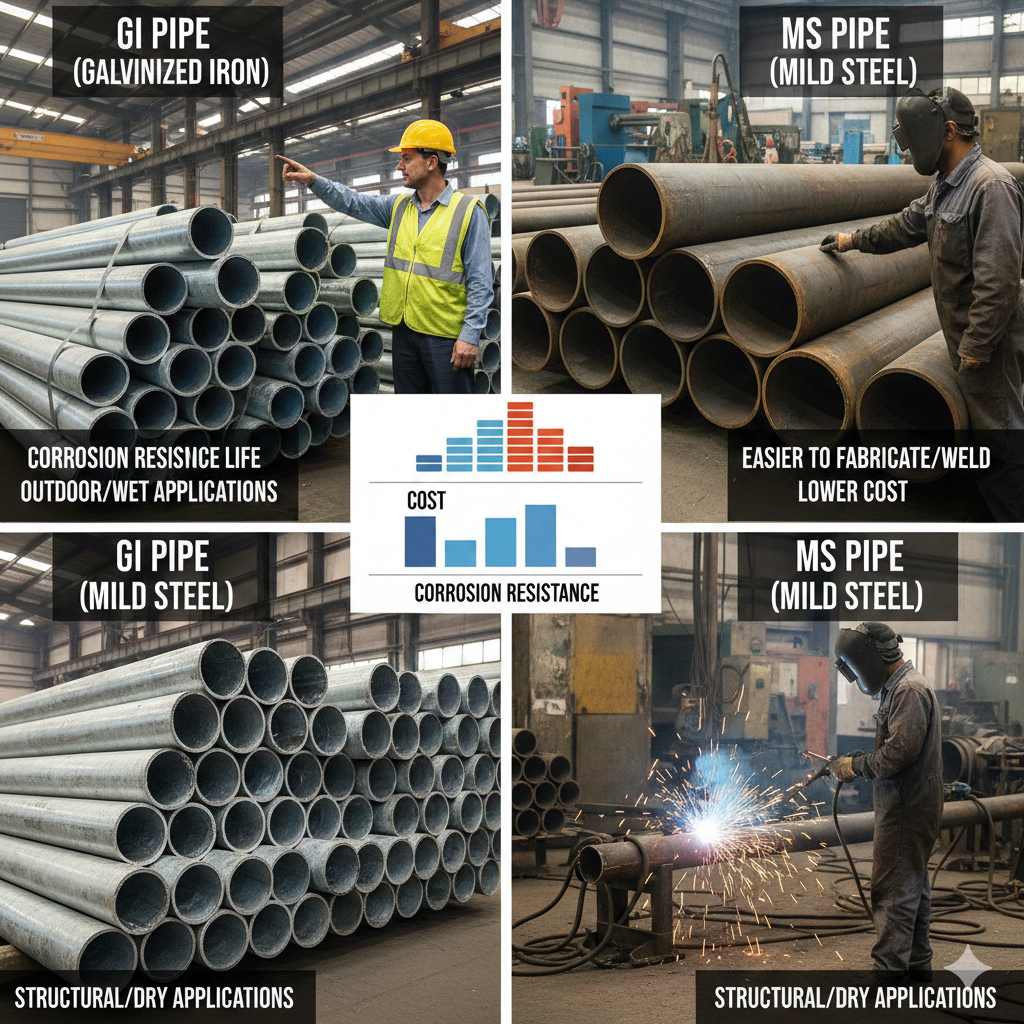

5. Performance Comparison Chart

Performance Index (Scale 1–10)

Corrosion Resistance: GI=6 | MS=3 | SS=10

Strength: GI=7 | MS=8 | SS=8

Cost Efficiency: GI=8 | MS=9 | SS=4

Maintenance Need: GI=5 | MS=6 | SS=9

6. When Should You Choose Which?

Choose a GI pipe for outdoor plumbing and mid-range structural work.

Choose an MS for industrial fabrication and welding-heavy tasks.

Choose an SS for chemical, food, or premium utility installations.

If you want deeper details on stainless materials, explore our earlier blog on SS pipe, which explains grades, performance, and industrial behavior.

7. How Udhhyog Helps B2B Buyers

Udhhyog and its products support buyers across industries by providing multiple types and sizes in one place at affordable rates. B2B businesses, contractors, fabricators, and traders can source all materials quickly without depending on multiple suppliers.

Conclusion

Choosing the right pipe saves time, money, and long-term maintenance costs. The right choice depends on project load, corrosion exposure, budget, and fabrication needs. Now that you understand the differences, which material will you choose for your next project, and would you like help sourcing it today?