Short Intro

The first time I saw a fabrication crew struggle with mismatched pipe sizes, I understood the real cost of confusion. That moment showed how essential the correct understanding SS pipe size is for smooth project timelines and predictable budgets.

Why Size Matters in Industrial SS Piping

Piping decisions shape every project stage. B2B buyers, construction contractors, fabricators, and plumbing firms depend on accurate size selection because incorrect choices create delays. This article on Understanding SS Pipe also connects naturally with our previous detailed blog on SS pipe applications and quality, which readers often explore for deeper insight.

Industries now prefer stainless steel piping due to its durability. According to the World Steel Association, stainless steel demand grows around 3% yearly, driven by construction and infrastructure upgrades. These numbers show how essential the correct pipe specification is during procurement.

SS Pipe Size Reference Chart

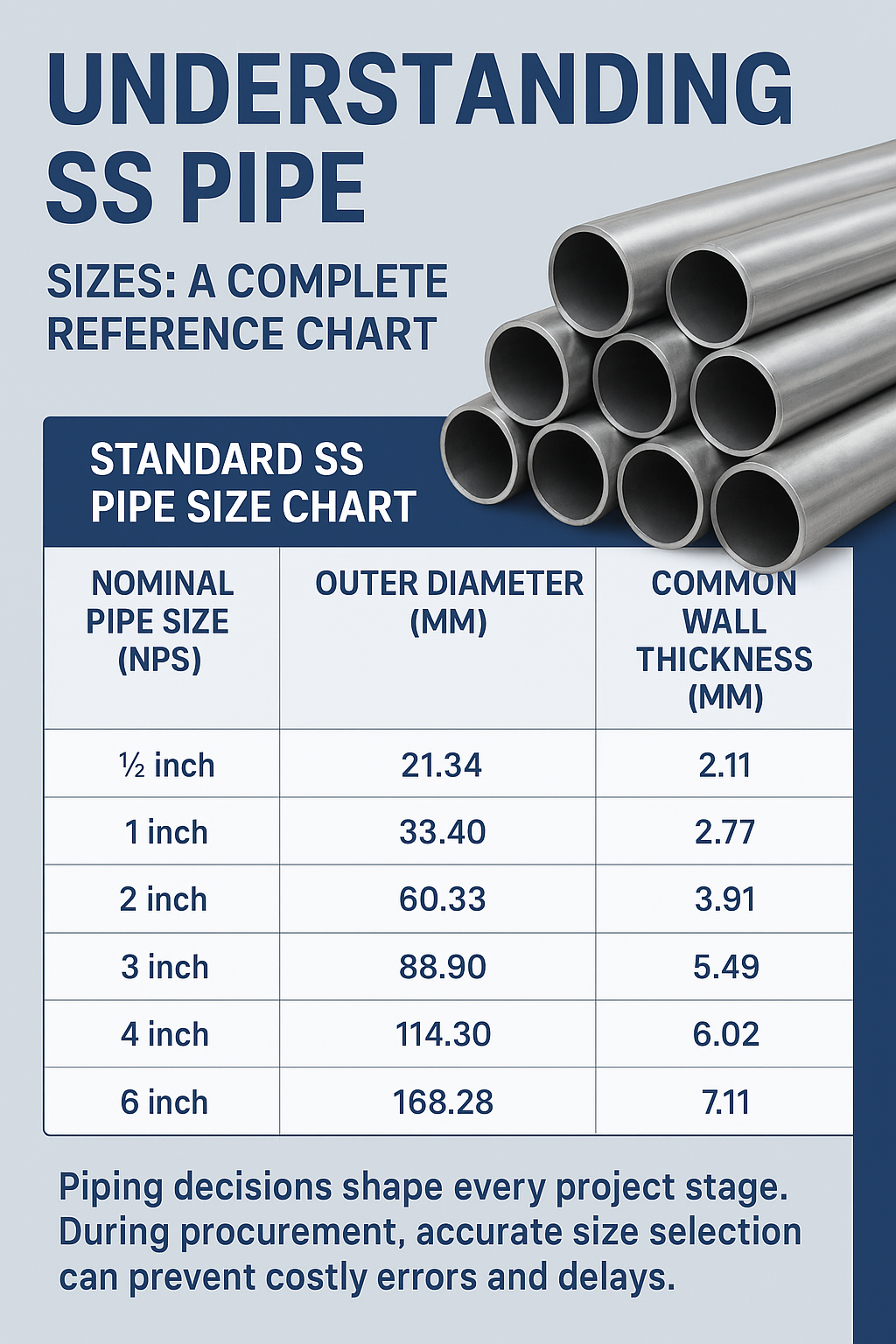

Below is a simplified chart used widely by contractors and fabricators for quick reference.

Standard SS Pipe Size Chart

| Nominal Pipe Size (NPS) | Outer Diameter (mm) | Common Wall Thickness (mm) |

|---|---|---|

| ½ inch | 21.34 | 2.11 |

| 1 inch | 33.40 | 2.77 |

| 2 inch | 60.33 | 3.91 |

| 3 inch | 88.90 | 5.49 |

| 4 inch | 114.30 | 6.02 |

| 6 inch | 168.28 | 7.11 |

These values follow standard ASME dimensional guidelines used across fabrication yards and industrial markets.

Where SS Pipe Sizes Are Used

Correct sizing is essential in many professional settings. Construction companies use larger diameters for structural frames, while plumbing networks rely on small and mid-range sizes. Industrial fabricators often source size-specific pipes for pressure vessels, dairy lines, or chemical flow systems.

Hardware dealers and traders benefit from stocking versatile sizes because most B2B buyers request immediate dispatch. Precise size mapping reduces waste and mismatch during installation.

Comparing SS Pipe Sizes in Different Grades

Grade selection influences size practicality. For example:

-

SS 304 suits plumbing, architecture, and food industries.

-

SS 316 handles harsh chemical zones.

-

SS 202 appears in cost-sensitive markets.

Larger diameters in SS 316 remain expensive due to alloy composition. Many contractors compare grades before deciding because grade and size together influence safety standards.

Price Range of SS Pipes in India

Understanding SS pipe pricing varies based on grade and dimensions. Industry estimates for 2025 show:

-

Small sizes (½ to 1 inch): ₹180–₹340 per kg

-

Mid sizes (1 to 3 inch): ₹200–₹380 per kg

-

Larger sizes (4 inch and above): ₹240–₹420 per kg

Price averages come from fabricator and wholesale market assessments across Delhi and Mumbai.

Key Factors Affecting SS Pipe Price

1. Size

Larger pipes use more raw material. Bigger diameters also require stronger forming tools.

2. Grade Composition

Higher nickel and molybdenum content push prices upward. Grade selection directly impacts budget planning.

3. Market Demand

Infrastructure booms increase demand. Seasonal bulk orders often raise rates temporarily.

4. Manufacturing Method

ERW, seamless, and welded pipes differ widely in production cost. Seamless pipes generally cost more.

5. Surface Finish

Polished, matte, or special finishes change the final rate because they need additional processes.

How Udhhyog Supports B2B Buyers

Udhhyog provides a wide range of pipe sizes and types at affordable rates, helping B2B businesses, contractors, industrial fabricators, plumbing firms, and hardware traders find everything in one place. This saves time during procurement and reduces sourcing complexity.

Conclusion

Choosing the correct SS pipe size ensures project stability, predictable costing, and long equipment life. Now that you understand sizing, pricing, and factors influencing SS pipe selection, are you ready to explore more and pick the right material for your next project?

Contact us today for expert guidance and quotations. What size do you need next?