The monsoon afternoon was quiet when a contractor called saying his project had stalled.

He needed piping urgently but was confused between GI vs MS options.

His situation reflects a common challenge for many industrial buyers today.

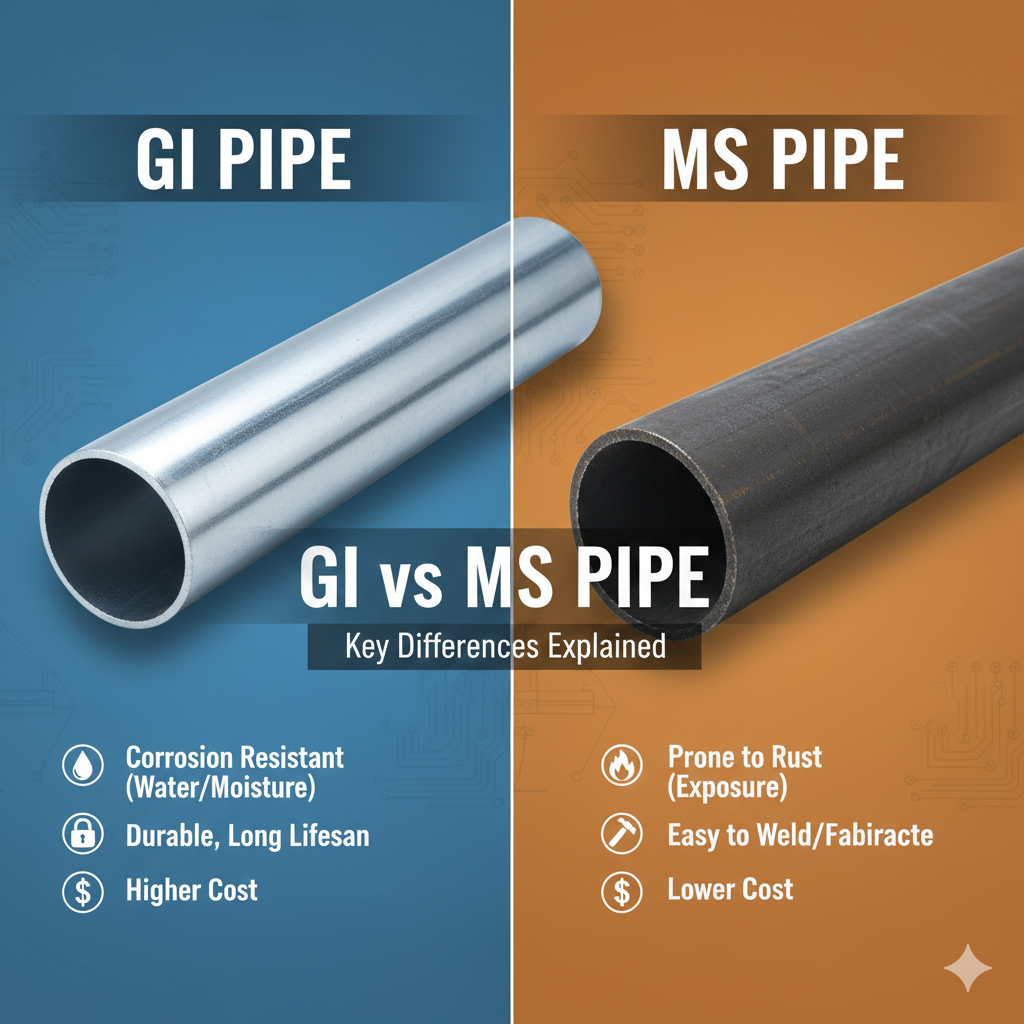

Understanding GI vs MS Pipes

Businesses across India rely on steel piping for construction, fabrication, and infrastructure work.

Choosing between GI vs MS pipes impacts project cost, durability, and long-term performance.

Recent data from the Bureau of Indian Standards (BIS) shows both materials dominate more than 70 percent of the domestic pipe demand in development projects.

This article explains GI vs MS applications, price behaviour, and selection factors for B2B buyers.

What Are GI Pipes?

GI pipes are mild steel pipes coated with zinc.

The zinc layer allows better resistance to rust.

Buyers in water supply, outdoor construction, and exposed installations often choose them.

Industry estimates from the Indian Steel Association show that GI pipe consumption grows nearly 8 percent each year due to rural and smart-city projects.

What Are MS Pipes?

MS pipes are plain mild steel pipes without zinc.

They are widely used in fabrication, structures, and general engineering.

Their welding flexibility makes them ideal for contractors requiring frequent on-site modifications.

Demand for MS pipes remains stable due to their economic pricing and availability in many size ranges.

GI vs MS Direct Application Comparison

Different industries use each pipe type for specific needs.

The table below summarises their typical B2B applications.

Application Table

| Feature / Use Case | GI Pipes | MS Pipes |

|---|---|---|

| Corrosion exposure | Better resistance | Needs coating |

| Plumbing systems | Common choice | Used in internal lines |

| Fabrication work | Limited flexibility | Highly preferred |

| Outdoor structures | Ideal | Requires paint |

| Cost variation | Higher | Lower |

| Lifespan | Longer in moisture | Moderate |

Price Comparison in GI vs MS

Market research from Engineering Goods Council India indicates the average price gap between GI vs MS pipes can range from 20 to 35 percent, depending on zinc coating weight, diameter, and steel grade.

Contractors prefer MS during bulk purchase because it lowers initial project cost.

GI becomes the preferred choice when long-term maintenance cost must remain low.

Graph: General Cost Difference Trend

(Simple text-based representation for article integration)

GI shows a higher band due to coating cost.

Factors Affecting GI vs MS Prices

1. Steel Grade

Higher grade steel increases strength and cost in both types.

Industrial fabricators choose specific grades for load-bearing work.

2. Zinc Coating Weight (for GI)

More coating increases durability.

The zinc amount significantly affects the GI vs MS price gap.

3. Pipe Diameter and Thickness

Thicker pipes cost more.

Large-bore pipes show bigger price differences.

4. Market Supply & Demand

Seasonal demand swings impact both categories, especially during infrastructure cycles.

5. Processing and Testing

MS pipes require simple processing.

GI pipes require an additional galvanizing stage which raises cost.

How GI vs MS Influences Project Performance

Construction companies consider moisture exposure and weld frequency before selecting material.

Fabricators choose MS when structural strength and easy modification matter.

Plumbing and infrastructure teams choose GI when water flow reliability matters.

Hardware traders prefer stocking both because demand patterns change weekly.

Connecting to Your Previous SS Pipe Article

Buyers comparing GI vs MS often research stainless steel options too.

Your previous article on SS pipe selection helps them explore premium alternatives for corrosion-critical projects.

How udhhyog and Its Pipe Products Support Your Needs

Udhhyog and its pipe products provide B2B buyers, contractors, fabricators, plumbing companies, and hardware traders a complete range of GI, MS, and other pipe types in many sizes at affordable rates in one place.

Conclusion

Choosing between GI vs MS pipes depends on exposure, fabrication needs, project scale, and long-term budget planning.

This comparison helps every industrial buyer make smarter decisions, but what specification do you need for your project today—shall we guide you further?