Introduction

A site engineer once told me how a wrong GI Pipe estimate delayed a major project.

The team ordered lighter pipes, which bent during installation.

That incident reminds us why accurate GI Pipe weight matters every single day.

Understanding GI Pipe Weight

GI Pipe defines the strength, durability, and load capacity of the pipe.

Buyers use this information to avoid failures in construction and industrial work.

The term GI Pipe also helps traders and contractors estimate handling and transport needs.

Accurate GI Pipe data supports project planning and reduces waste.

Industries check GI Pipe before choosing fabrication methods.

Raw material quality decides GI Pipe variations.

Uniform GI Pipe ensures smooth work on sites.

Every professional should check GI Pipe before placing bulk orders.

Even pipe threading machines perform better with correct GI Pipe .

Applications in B2B and Industrial Sectors

B2B buyers rely on GI pipes for structural lines, water systems, and cable routing.

GI Pipe decides suitability for medium or heavy-load applications.

Construction contractors use GI Pipe tables for scaffolding planning.

Industrial fabricators consider GI Pipe before welding or bending tasks.

Plumbing companies choose pipes based on GI Pipe for repair work.

Hardware traders demand exact GI Pipe to guide buyers confidently.

Our previous blog on SS pipe also highlights material selection challenges.

Both topics connect well for buyers comparing long-term performance across projects.

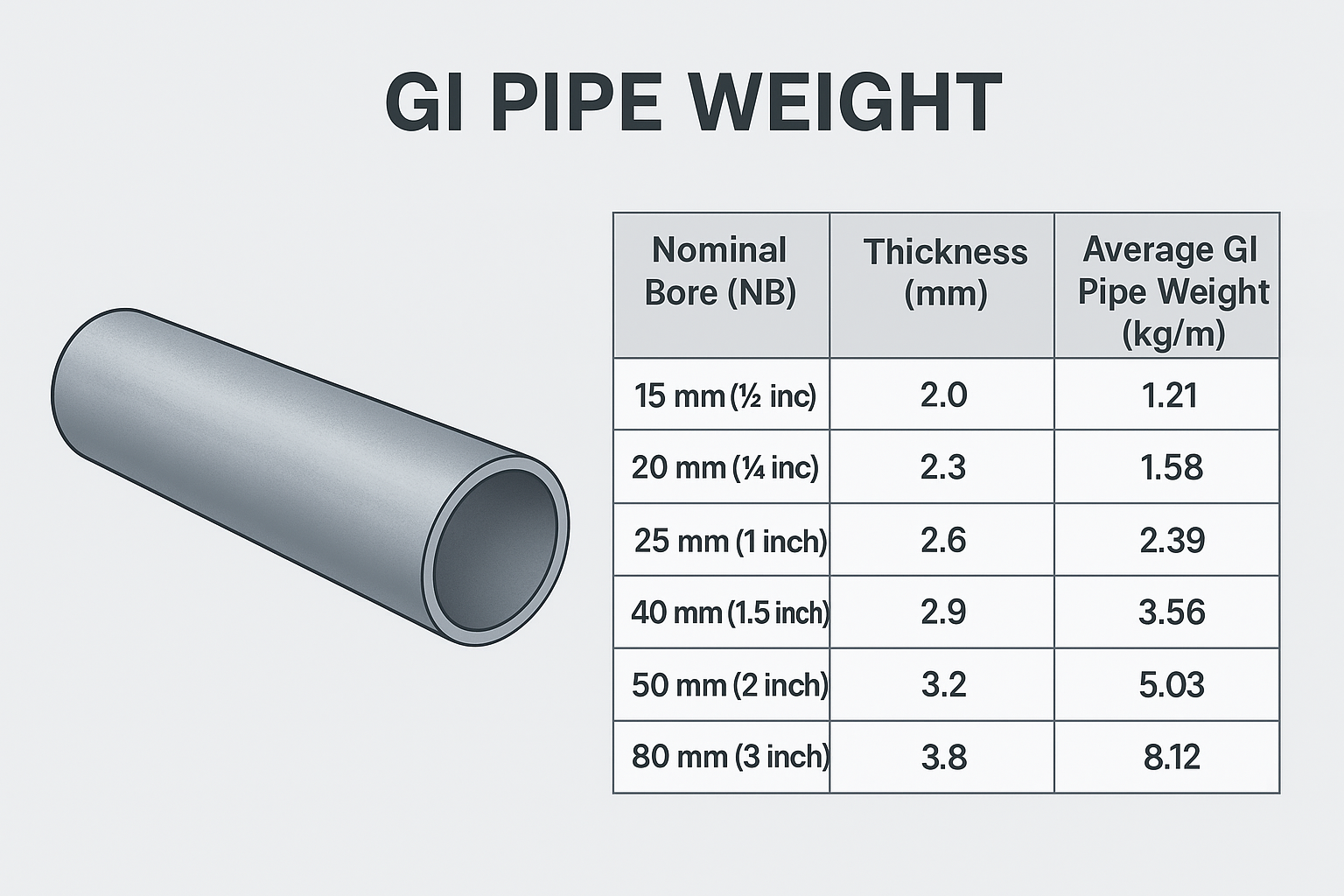

Comparison of GI Pipe Weight Through Table

Below is a reference table showing common sizes and average weights:

GI Pipe Weight Table

| Nominal Bore (NB) | Thickness (mm) | Average GI Pipe Weight (kg/m) |

|---|---|---|

| 15 mm (½ inch) | 2.0 | 1.21 |

| 20 mm (¾ inch) | 2.3 | 1.58 |

| 25 mm (1 inch) | 2.6 | 2.39 |

| 40 mm (1.5 inch) | 2.9 | 3.56 |

| 50 mm (2 inch) | 3.2 | 5.03 |

| 80 mm (3 inch) | 3.8 | 8.12 |

Source: Standard industrial pipe weight charts (IS 1239 data).

Prices and Market Trends

GI Pipe directly affects pricing.

Heavier pipes cost more due to higher zinc consumption.

Manufacturing cost rises with thickness and coating quality.

Traders review GI Pipe before quoting bulk prices.

Market prices depend on several key factors:

-

Steel and zinc rate movements

-

Size and GI Pipe variations

-

Fabrication and handling cost

-

Supply chain delays

-

Seasonal construction demand

Companies compare GI Pipe across suppliers before choosing a vendor.

Accurate GI Pipe helps buyers avoid overpriced products.

Factors Affecting GI Pipe Price

The following elements influence GI Pipe pricing in India:

1. Raw Material Grade

Better grade steel gives higher GI Pipe consistency.

2. Zinc Coating Thickness

More coating increases GI Pipe and final cost.

3. Pipe Size and Length

Bigger pipes and higher GI Pipe raise transportation charges.

4. Production Standards

IS-compliant units keep GI Pipe more accurate.

5. Market Conditions of gi pipe weight

Demand and supply shifts affect GI Pipe weight-based pricing models.

One-Time Mention: How Udhhyog Supports Buyers

Udhhyog and its pipe Products offer B2B buyers many types and sizes in one place at affordable rates.

This helps construction contractors, industrial fabricators, plumbing companies, and hardware traders streamline bulk purchases.

Buyers compare GI Pipe weight easily and select the right option without delays.

Conclusion

GI Pipe weight plays a major role in every industrial and construction decision.

It shapes pricing, performance, applications, and transport planning.

Professionals must check GI Pipe weight before ordering to avoid costly project errors.

Now that you understand GI Pipe clearly, what specification do you want to explore next for your business?