Few months ago, a contractor shared his struggle with delayed projects. His orders failed due to wrong GI pipe specifications. That mistake cost him time and money. Many B2B buyers face the same issue today.

Understanding correct GI pipe specifications helps you avoid material mismatch, project failures, and cost overruns.

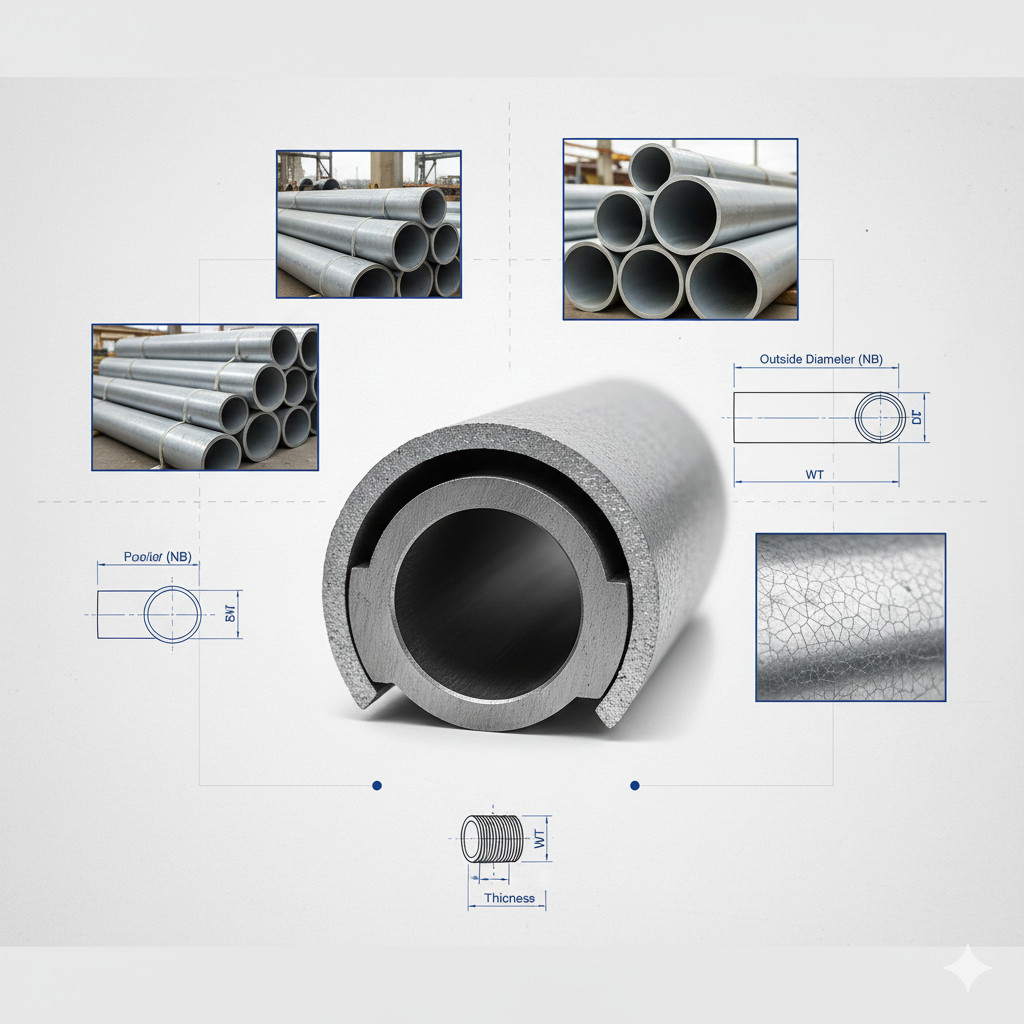

What Are GI Pipe Specifications?

GI pipe specifications describe size, thickness, weight, coating grade, and pressure rating.

Construction contractors, fabricators, and plumbing agencies depend on accurate data for stable designs.

These pipes follow standards like IS 1239, IS 3589, ASTM A53, and BS 1387.

Each standard defines mechanical strength, coating quality, and structural performance.

Key GI Pipe Specifications Table

Here is an easy table for quick technical reference:

| Specification Type | Range / Value | Standard Used |

|---|---|---|

| Nominal Bore Size | 15mm–300mm | IS 1239 / IS 3589 |

| Wall Thickness | 2mm–10mm | Light, Medium, Heavy Class |

| Zinc Coating | 120–300 g/m² | IS 4736 |

| Density | 7.85 g/cm³ | Industry Average |

| Yield Strength | 195–240 MPa | IS 1239 |

| Pressure Rating | 2.5–6 MPa | Class A/B/C |

These GI pipe specifications guide major B2B purchases and help avoid structural risks.

Applications Based on GI Pipe Specifications

Different works use different GI pipe specifications depending on load, pressure, humidity, and soil conditions.

1. Construction and Scaffolding

Contractors prefer heavy-class pipes because they carry high loads.

2. Fire-fighting Systems

Fire agencies use medium-class pipes due to pressure stability.

3. Water and Plumbing Lines

Plumbing companies choose class A or medium pipes.

4. Industrial Fabrication

Fabricators choose pipes with uniform zinc coating and strong weldability for support structures.

Accurate GI pipe specifications avoid failure in these applications and keep operations stable.

Comparison With Other Pipe Materials

You may have read our previous blog on SS pipe, where corrosion resistance plays a key role.

Comparing steel grades helps buyers choose wisely.

GI vs SS Pipes

-

GI pipes use zinc coating.

-

SS pipes use chromium-rich steel.

-

GI is cheaper.

-

SS has longer life.

-

GI suits water lines and scaffolding.

-

SS suits chemical and food industries.

Knowing these differences with clear GI pipe specifications helps select the right material.

GI Pipe Price Trends 2025

Buyers track pricing closely before major orders.

The average market price in India for 2025 remains between ₹70–₹95 per kg depending on GI pipe.

Price by Size (Indicative Range)

-

1-inch NB: ₹120–₹150 per meter

-

2-inch NB: ₹240–₹300 per meter

-

3-inch NB: ₹360–₹450 per meter

Prices change due to different zinc coating and wall thickness.

Factors Affecting GI Pipe Price

The final price depends heavily on GI pipe and material quality.

1. Wall Thickness

Thicker pipes require more steel.

This increases cost.

2. Zinc Coating Weight

Higher coating = higher price.

Coating between 120–300 g/m² changes price significantly.

3. Steel Grade

IS 1239 material is cheaper than IS 3589 due to lower thickness.

4. Manufacturing Method

ERW welded pipes cost less than seamless pipes.

5. Market Demand

Seasonal construction trends impact cost of pipes.

Understanding these variables helps businesses negotiate better with suppliers.

How Udhhyog and Its Pipe Products Help Buyers

Udhhyog and its pipe products serve B2B buyers with a wide range of sizes and grades.

Construction contractors, fabricators, plumbing companies, and traders get all materials in one place.

They receive consistent quality, reliable sizing, and affordable rates based on exact GI pipe.

Conclusion

Choosing the correct GI pipe ensures safety, durability, and cost control for every project.

Accurate specification knowledge prevents failures and improves efficiency.

Before placing your next bulk order, would you like expert help selecting the perfect pipe specifications for your project?

Contact us today.