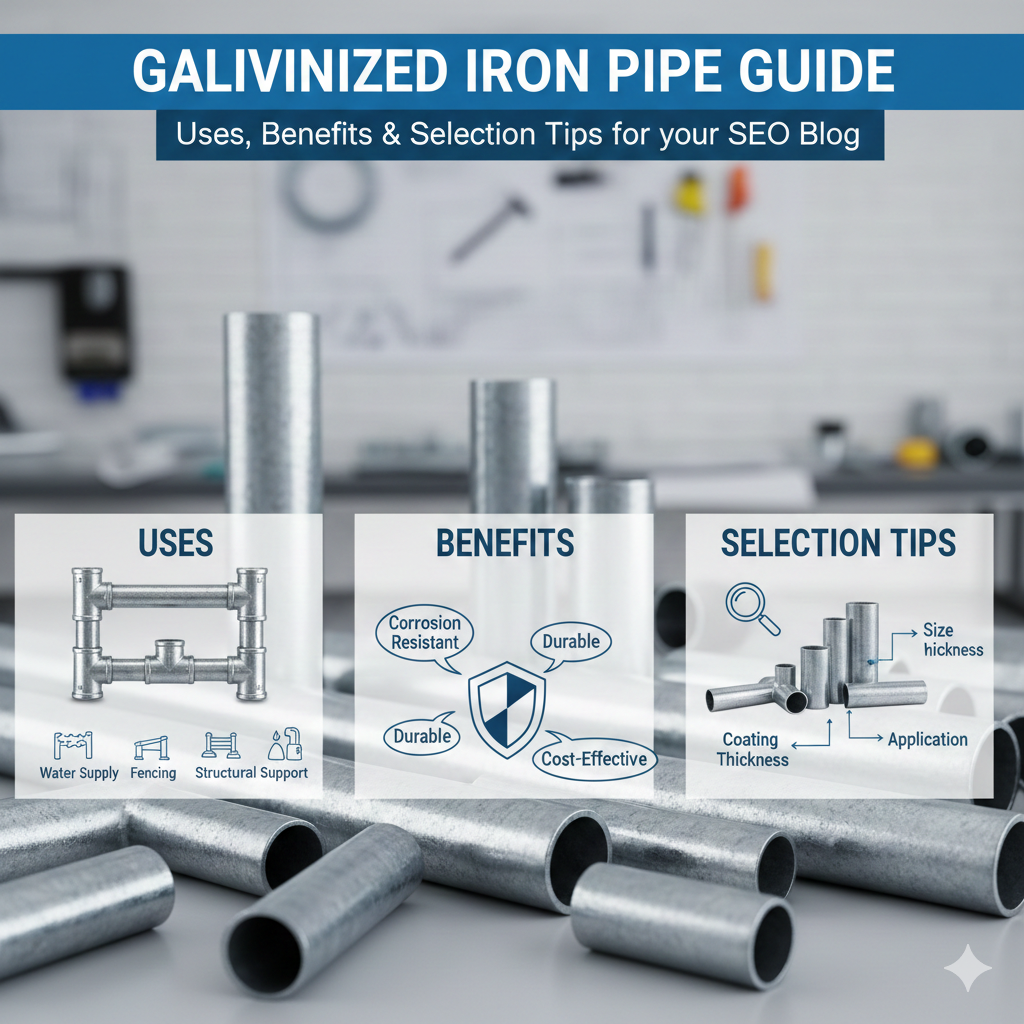

Galvanized Iron Pipes have supported India’s construction growth for decades. Whether it is a new building, a large industrial setup, or a small water system, these pipes remain a trusted choice. Many engineers still prefer them because they deliver strength, safety, and long-term durability. This guide helps you understand everything about galvanized iron pipe, including uses, benefits, types, and how to select the right pipe for your project.

What Is a Galvanized Iron Pipe?

A galvanized iron pipe is a steel pipe coated with zinc to prevent rust. The zinc layer increases durability and protects the pipe from moisture and corrosion. These pipes are known for long service life and consistent performance in various environments.

Why Galvanized Iron Pipes Are Preferred

Industries trust GI pipes because of their proven performance. According to several industry surveys, zinc-coated pipes last much longer than non-coated metal pipes. Studies show that GI Pipes can remain corrosion-free for many years under normal conditions. Their mechanical strength also makes them suitable for heavy-duty work.

Major Uses of Galvanized Iron Pipes

1. Water Supply Systems

GI pipes are used in residential and commercial water distribution. They handle high pressure well. Their corrosion-resistant coating makes them safe for long-term water flow.

2. Agriculture & Irrigation

Farmers use GI pipes for borewell installation, water lines, and sprinkler systems. Their rugged construction supports extensive field use.

3. Industrial Applications

Industries use these pipes for air lines, chemical transport, oil handling, and structural supports. Their strength makes them ideal for machinery frameworks.

4. Construction & Infrastructure

Builders use GI pipes for scaffolding, fencing, poles, gates, and building supports. Their load-bearing capacity adds reliability to the structure.

5. Firefighting Systems

Because GI pipes can handle pressure, they are widely used in fire suppression lines and safety networks.

Advantages of Galvanized Iron Pipes

1. Long Life

The zinc coating protects the pipe from corrosion. This increases lifespan and reduces replacement cost.

2. High Strength

GI pipes are tough and perform well under pressure. They don’t deform easily.

3. Weather Resistant

They stay strong in rain, heat, and moisture. This makes them suitable for outdoor installations.

4. Cost Effective

GI pipes offer long-term value. They require less maintenance and provide reliable performance for years.

5. Safe for Water Supply

The protective layer keeps water contamination risks low. This makes them ideal for households and industries.

Types of Galvanized Iron Pipes

Choosing the right type is important for performance. Here are the common categories:

1. Light Class (A)

Used for low-pressure applications like light water supply and fencing.

2. Medium Class (B)

A popular choice for construction and general engineering work.

3. Heavy Class (C)

Used in high-pressure lines, industrial setups, and firefighting systems.

How to Choose the Right Galvanized Iron Pipe

1. Identify the Purpose

Choose the pipe class based on the pressure and environment.

Heavy-duty projects require Class C. General construction works well with Class B.

2. Check the Coating Quality

Uniform zinc coating ensures long service life. Look for smooth surface and consistent thickness.

3. Confirm Size and Diameter

Choose the right diameter for water flow or load capacity. Buildings and factories often use larger diameters.

4. Examine Weight and Wall Thickness

A thicker wall provides better strength. Industries prefer these for long-term durability.

5. Verify Standards and Grades

Pipes manufactured under approved standards deliver safer performance.

Why Galvanized Iron Pipes Remain in Demand

Market data shows continuous growth in the steel pipe sector. Demand for GI Pipes remains strong due to infrastructure expansion, urban development, and agricultural needs. Their versatility keeps them relevant across all industries.

Final Thoughts

Galvanized iron pipes offer strength, safety, and value. Whether you need them for water lines, construction, industrial work, or irrigation, they deliver consistent performance. Choosing the right pipe improves durability and reduces long-term cost. With proper selection and installation, GI pipes become a reliable part of any project.