Introduction to Coupling Pipe Fittings

A pipe coupling is a short-length fitting used to connect two pipes together. It can join pipes of the same size or different sizes, and can be permanent (welded) or removable (threaded). Couplings are among the most versatile and widely used pipe fittings, playing a crucial role in plumbing, oil & gas, irrigation, and firefighting systems.

This article explains:

- Types of coupling pipe fittings

- Materials used

- Connection methods

- Applications across industries

- International standards (IS, ASTM, DIN, JIS)

- Selection guide

👉 For a complete overview, check our Pipe Fittings – Complete Guide

Types of Coupling Pipe Fittings

1.1 Half Coupling

- Joins a pipe to another fitting or piece of equipment.

- One end has threads/welding end, the other is plain.

- Common in small-diameter pipelines and equipment connections.

1.2 Full Coupling

- Connects two pipes of equal size.

- Can be threaded, welded, or socket type.

- Common in plumbing, oil pipelines, and irrigation.

1.3 Reducing Coupling

- Connects pipes of different diameters.

- Maintains flow between large and small pipelines.

- Used in industrial and firefighting systems.

1.4 Screwed/Threaded Coupling

- Internal threads on both ends.

- Easy to install and dismantle.

- Ideal for low-pressure and small-bore piping.

1.5 Compression Coupling

- Uses a mechanical nut & ferrule system.

- Leak-proof, requires no welding or threading.

- Used in PVC, HDPE, and irrigation pipelines.

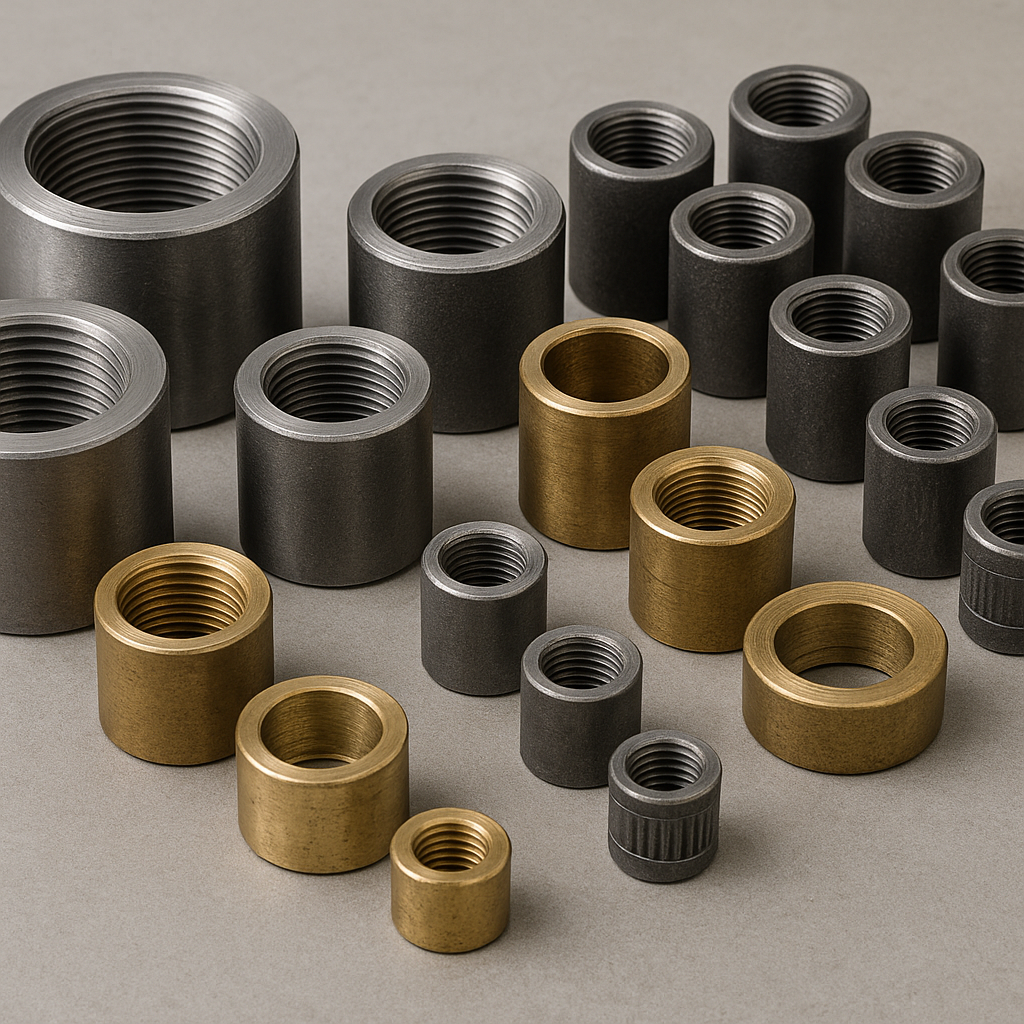

Materials Used in Coupling Fittings

Metallic Couplings

- Mild Steel (MS): Welding pipelines, economical.

- Stainless Steel (SS 304/316): Corrosion resistant, food, pharma, and oil industries.

- Galvanized Iron (GI): Domestic plumbing, firefighting.

- Copper & Brass: HVAC and refrigeration.

- Cast Iron/Ductile Iron: Sewage and heavy-duty pipelines.

Non-Metallic Couplings

- PVC & CPVC: Plumbing, low-pressure pipelines.

- HDPE: Irrigation and agriculture.

- PPR/PP: Hot & cold water supply systems.

Connection Types of Coupling Fittings

- Threaded Coupling – Small pipelines, easy dismantling.

- Butt Weld Coupling – Permanent, industrial use.

- Socket Weld Coupling – High pressure, small bore.

- Flanged Coupling – Bolted, large diameter pipelines.

- Compression Coupling – No welding, quick install.

Applications of Coupling Pipe Fittings

Plumbing & Water Supply – GI threaded couplings.

- Oil & Gas Pipelines – Welded MS/SS couplings.

- Firefighting Systems – GI reducing couplings.

- Irrigation & Agriculture – HDPE compression couplings.

- HVAC Systems – Brass & copper couplings.

Standards for Coupling Pipe Fittings

Couplings follow international standards for dimensions & pressure ratings:

- IS (India): IS 1239, IS 1538 for MS/GI couplings.

- ASTM/ASME (USA): ASTM A105, ASTM A234, ASME B16.11.

- DIN/EN (Europe): DIN 2986, EN 10241.

- JIS (Japan): JIS B2311, B2312.

Difference Between Full, Half & Reducing Coupling

| Feature | Full Coupling | Half Coupling | Reducing Coupling |

|---|---|---|---|

| Connection | Pipe to Pipe | Pipe to Equipment | Large to Small pipe |

| Size | Same diameter | One end plain | Different diameters |

| Cost | Standard | Lower | Slightly higher |

| Applications | Plumbing, oil pipelines | Equipment joints | Firefighting, irrigation |

How to Select the Right Coupling

Match pipe size (NB/OD).

- Choose material (MS, SS, GI, PVC, HDPE).

- Decide based on connection type (threaded, welded, compression).

- Ensure compliance with standards (IS, ASTM, DIN).

- Consider application (domestic, industrial, firefighting).

Conclusion

Coupling pipe fittings are essential in both domestic plumbing and industrial pipelines. From full couplings for equal-size pipes to reducing couplings for mismatched diameters, they play a crucial role in ensuring leak-proof connections.